Industrial lighting is essential for workplace safety, efficiency, and productivity. A well-functioning system ensures reliable illumination, but when circuit breakers keep tripping, it can lead to operational disruptions, equipment damage, and safety risks.

A constantly tripping breaker signals an underlying electrical issue that must be addressed. Ignoring it can result in costly repairs, downtime, or even fire hazards. The key to preventing these problems is understanding their root causes—such as overloaded circuits, faulty wiring, or power surges—and implementing effective solutions.

Partnering with experienced industrial electrical contractors helps identify and resolve electrical faults before they escalate. Additionally, consulting a skilled industrial commercial lighting electrician ensures your lighting system is properly installed and maintained for optimal performance.

Understanding Circuit Breaker Trips in Industrial Lighting Systems

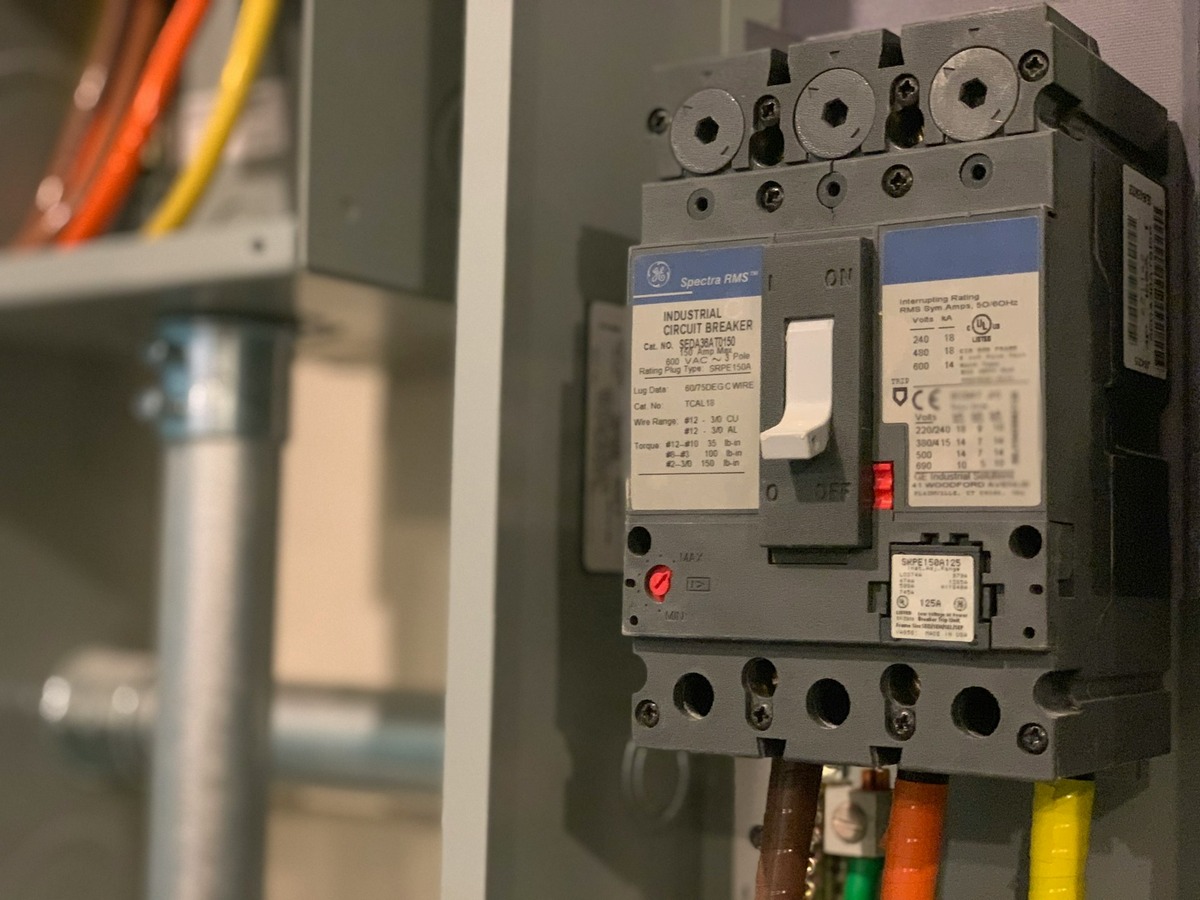

A circuit breaker is a crucial safety device that interrupts electrical flow when it detects issues like overloads, short circuits, or ground faults. In industrial settings, where lighting systems consume substantial power, frequent breaker trips can occur if electrical loads are not properly distributed.

When a breaker trips, it shuts off power to the affected circuit to prevent overheating, electrical fires, and equipment damage. While this safety feature protects the system, repeated tripping indicates a deeper electrical issue that requires immediate attention.

Understanding the common causes of breaker trips—such as faulty wiring, excessive power demand, or defective lighting fixtures—can help in diagnosing and resolving the problem efficiently. Working with experienced industrial electrical contractors ensures a proper assessment, while a skilled industrial commercial lighting electrician can help maintain and optimise your lighting system for safe, uninterrupted operation.

Common Causes of Breaker Trips in Industrial Lighting

Overloaded Circuits and Excessive Power Demand

One of the most common reasons for a circuit breaker to trip in an industrial lighting system is an overloaded circuit. Industrial lighting fixtures, particularly high-intensity discharge (HID) lights, metal halide lamps, and large-scale LED installations, consume significant amounts of power. If too many lights are connected to a single circuit, the total electrical demand may exceed the breaker’s capacity.

When the breaker senses an overload, it trips to prevent overheating and potential electrical fires. This is particularly common in older facilities where electrical infrastructure was not designed to handle modern lighting requirements. Upgrading the electrical panel, redistributing the lighting load across multiple circuits, or replacing energy-intensive fixtures with energy-efficient LED lighting can help mitigate this issue.

Short Circuits Due to Faulty Wiring or Connections

A short circuit occurs when a live wire comes into contact with a neutral or ground wire, creating a direct and unintended pathway for electricity. This results in an excessive surge of current that causes the breaker to trip almost instantly. Short circuits can occur due to damaged wiring, loose connections, or faulty lighting fixtures.

In industrial settings, where electrical systems are often exposed to heavy use, extreme temperatures, and harsh conditions, wiring can deteriorate over time. Regular inspections and maintenance can help identify and fix damaged wires before they cause serious issues. Hiring experienced industrial electrical contractors to assess and repair faulty wiring is essential for preventing repeated short circuits.

Ground Faults and Moisture Exposure in Lighting Systems

Ground faults occur when an electrical current unintentionally flows to the ground instead of following its intended path. This can happen when a live wire comes into contact with metal conduits, electrical enclosures, or damp surfaces. Ground faults are particularly dangerous in industrial environments where moisture, humidity, and water exposure are common.

Water intrusion into lighting fixtures, junction boxes, or electrical panels can lead to ground faults that repeatedly trip circuit breakers. Ensuring that all electrical components are properly sealed, using waterproof fixtures, and installing ground fault circuit interrupters (GFCIs) can help mitigate these risks.

Faulty Lighting Fixtures, Ballasts, and LED Drivers

Malfunctioning lighting fixtures can also cause breaker trips. Older lighting technologies such as fluorescent and HID lamps rely on ballasts to regulate electrical current. When these ballasts degrade, they may cause irregular current flow, leading to frequent breaker trips.

Even modern LED lighting systems can experience electrical faults if LED drivers or transformers fail. Flickering lights, buzzing sounds, or inconsistent illumination are signs of potential ballast or driver failure. Replacing faulty components and upgrading to high-quality LED lighting can reduce the likelihood of electrical disruptions.

Power Surges and High Inrush Current at Startup

Industrial lighting systems often experience power surges when they are switched on, especially if multiple high-wattage fixtures are turned on simultaneously. This inrush current can momentarily exceed the breaker’s limit, causing it to trip. To address this issue, facilities can install soft-start ballasts or LED drivers that gradually increase power rather than drawing a sudden surge. Additionally, using surge protectors and ensuring that the electrical panel can handle the expected inrush current can prevent frequent breaker trips.

Loose or Deteriorated Wiring Connections

Loose electrical connections create resistance, which generates heat and increases the risk of circuit breaker trips. Over time, vibration, temperature fluctuations, and physical impact can cause wiring terminals to loosen, leading to intermittent faults and unexpected power disruptions.

Regular maintenance and inspections can help detect and correct loose connections before they become hazardous. A qualified industrial commercial lighting electrician can tighten connections, replace corroded wires, and ensure the electrical system remains secure and efficient.

How to Fix a Tripping Breaker in Industrial Lighting Systems

Conduct a Thorough Electrical Inspection

When a breaker trips repeatedly, the first step is to perform a detailed inspection of the electrical system. This includes checking breaker panels, wiring, lighting fixtures, and circuit loads for signs of wear, damage, or excessive power demand. Using thermal imaging cameras and insulation resistance testers can help detect hidden electrical faults.

Redistribute Lighting Loads Across Multiple Circuits

If an overloaded circuit is the cause of breaker trips, redistributing the lighting load across multiple circuits can balance the power demand. Upgrading to a higher-capacity breaker may be an option, but only if the existing wiring can handle the increased current without overheating.

Replace Faulty Fixtures, Ballasts, or LED Drivers

Lighting components that show signs of failure should be replaced immediately. Upgrading to modern LED lighting with efficient drivers can significantly reduce energy consumption and eliminate common issues associated with older lighting technologies.

Install Surge Protectors and Soft-Start Ballasts

To prevent power surges from tripping breakers, installing surge protectors can help regulate voltage fluctuations. Additionally, using soft-start ballasts or LED drivers can reduce the inrush current when lights are turned on, ensuring a smooth startup without overloading the circuit.

Seal and Waterproof Electrical Components

In environments prone to moisture exposure, ensuring that electrical enclosures, junction boxes, and fixtures are properly sealed can prevent ground faults and corrosion-related failures. Using industrial-grade waterproof fixtures and coatings can enhance the longevity of electrical components.

Hire a Professional Industrial Electrical Contractor

If breaker trips persist despite troubleshooting, consulting an experienced industrial electrical contractor is the best course of action. Professionals have the expertise to identify complex electrical issues, upgrade outdated systems, and ensure compliance with safety regulations.

Preventative Measures to Avoid Future Breaker Trips

Schedule Routine Maintenance and Inspections

Preventative maintenance is essential for ensuring the reliability of industrial lighting systems. Conducting regular electrical inspections, testing breakers, and checking for signs of wear or damage can help prevent unexpected failures.

Upgrade Electrical Infrastructure to Meet Modern Demands

Older industrial facilities may have outdated electrical systems that are not designed to handle modern lighting requirements. Upgrading electrical panels, wiring, and circuit breakers to meet current safety standards can significantly reduce the risk of breaker trips.

Train Employees on Electrical Safety and Awareness

Providing training on electrical safety can help employees identify warning signs of potential electrical failures, such as flickering lights, buzzing noises, or overheating fixtures. Early reporting and intervention can prevent major disruptions.

Work with Qualified Industrial Commercial Lighting Electricians

Partnering with skilled industrial commercial lighting electricians ensures that all electrical work is performed to the highest safety and efficiency standards. Professional electricians can design, install, and maintain lighting systems that are optimised for industrial environments.

Conclusion

A tripping circuit breaker in an industrial lighting system is a clear indicator of an electrical problem that requires immediate attention. Whether caused by overloaded circuits, faulty wiring, short circuits, or power surges, addressing the issue promptly is essential for maintaining workplace safety and operational efficiency. By conducting regular maintenance, upgrading outdated electrical systems, and working with expert industrial electrical contractors, businesses can prevent electrical failures and ensure reliable industrial lighting for years to come. If your facility is experiencing frequent breaker trips, consulting a professional industrial commercial lighting electrician can help diagnose and resolve the issue effectively.

Frequently Asked Questions (FAQs)

1. Why does my industrial lighting breaker keep tripping?

Frequent breaker trips occur due to overloads, faulty wiring, or short circuits. Consulting industrial electrical contractors can help diagnose and fix the issue for safe, uninterrupted operation.

2. Can faulty lighting fixtures cause circuit breakers to trip?

Yes, defective ballasts, LED drivers, or wiring issues can overload circuits. A qualified industrial commercial lighting electrician can inspect and replace faulty components to prevent frequent breaker trips.

3. How can I prevent my industrial lighting system from overloading circuits?

Distribute lighting loads across multiple circuits and upgrade outdated wiring. Hiring industrial electrical contractors ensures proper electrical design, reducing the risk of overloads and power disruptions.

4. What should I do if my breaker trips repeatedly?

Turn off the circuit and contact an industrial commercial lighting electrician to inspect wiring, breakers, and lighting fixtures for faults to ensure long-term electrical safety.

5. Can upgrading to LED lighting reduce breaker trips?

Yes, energy-efficient LEDs consume less power and reduce electrical strain. Consulting industrial electrical contractors helps with proper LED installation, ensuring optimal performance and reduced circuit breaker issues.